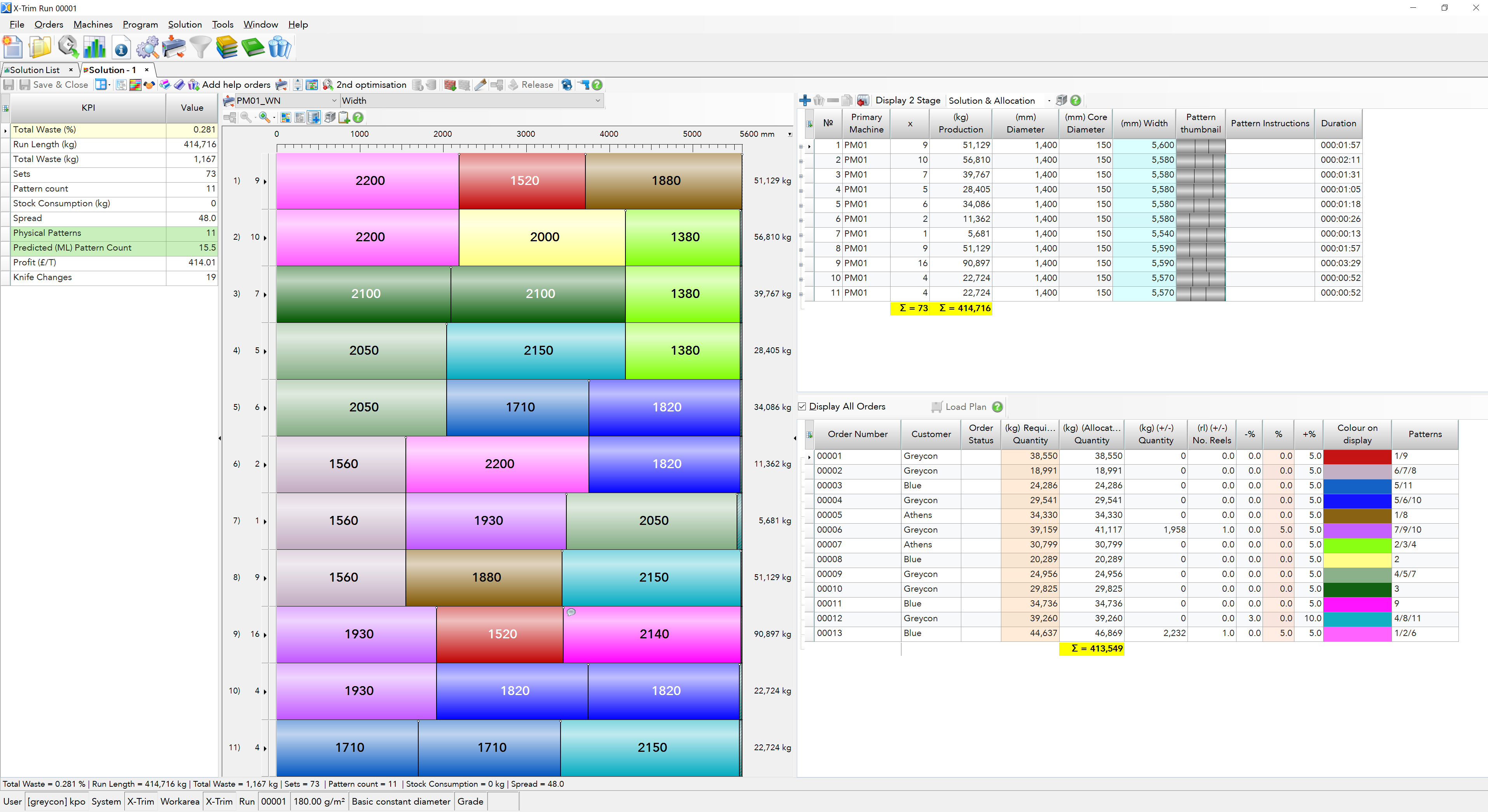

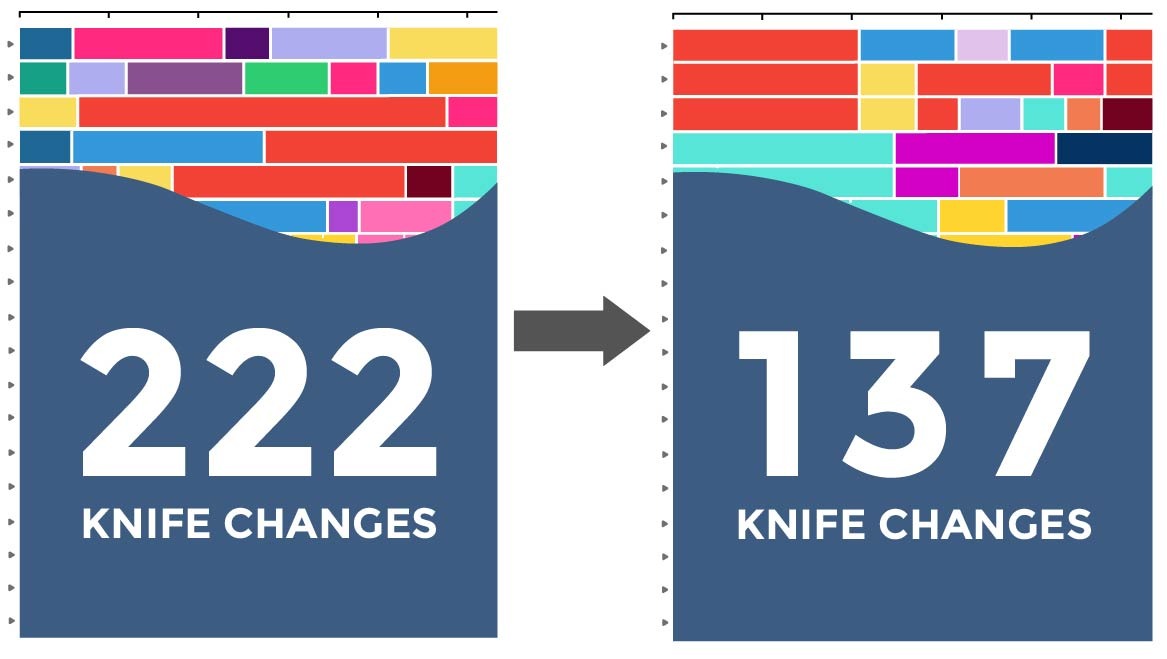

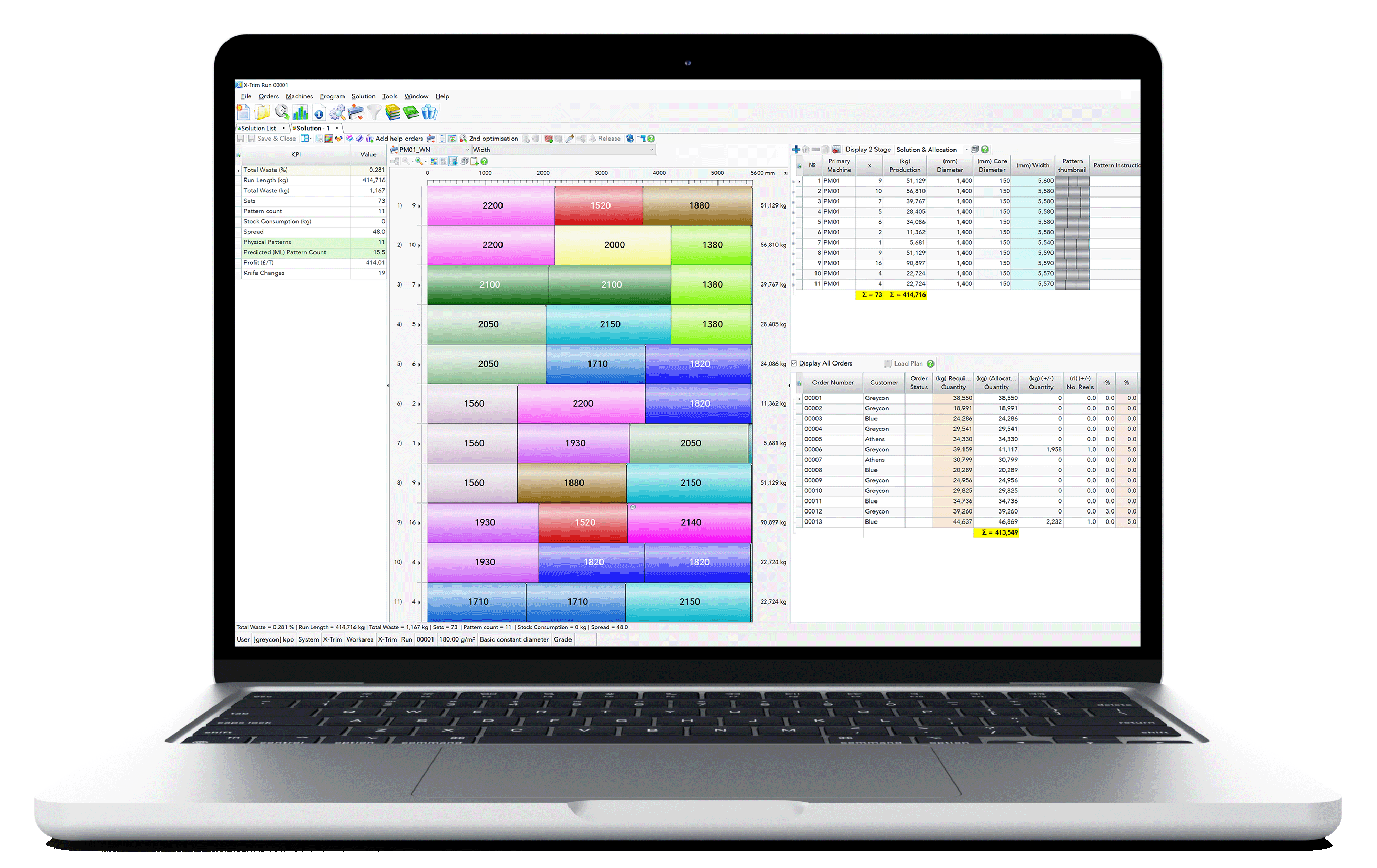

Reduced trim waste from primary slitting with patented algorithms designed to resolve the most complex of problems

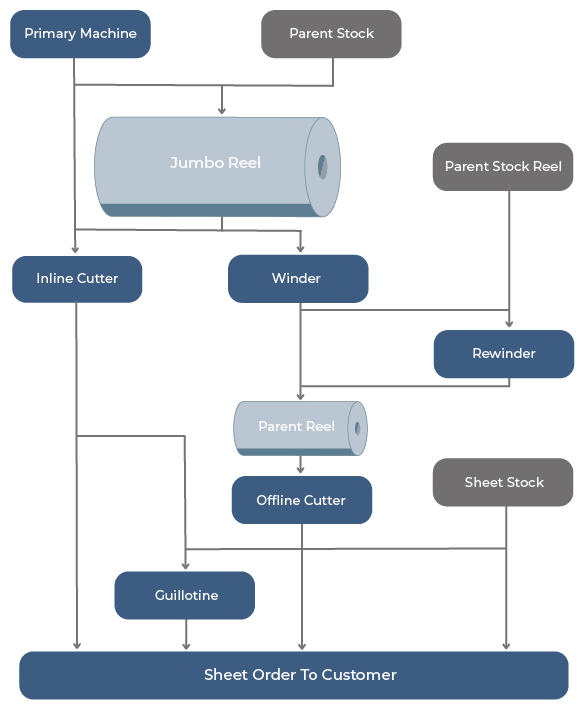

Meet customers orders using any mixture of finished and semi-finished products

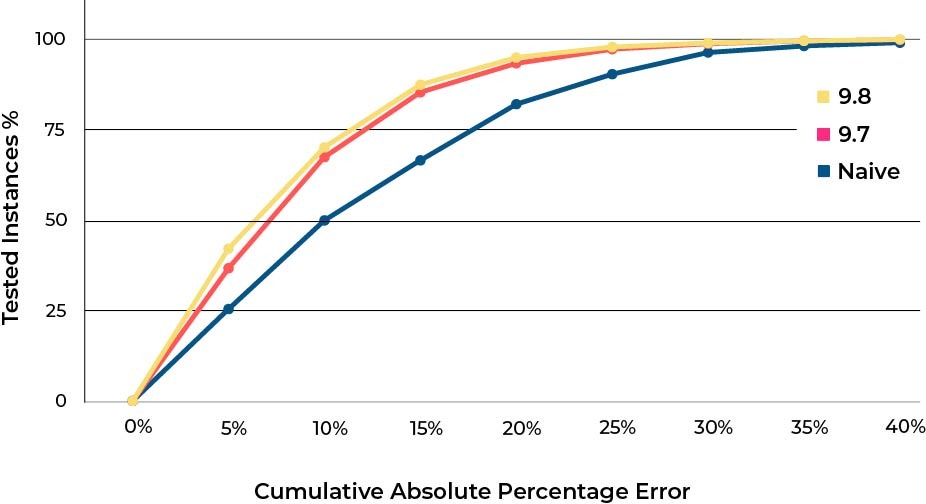

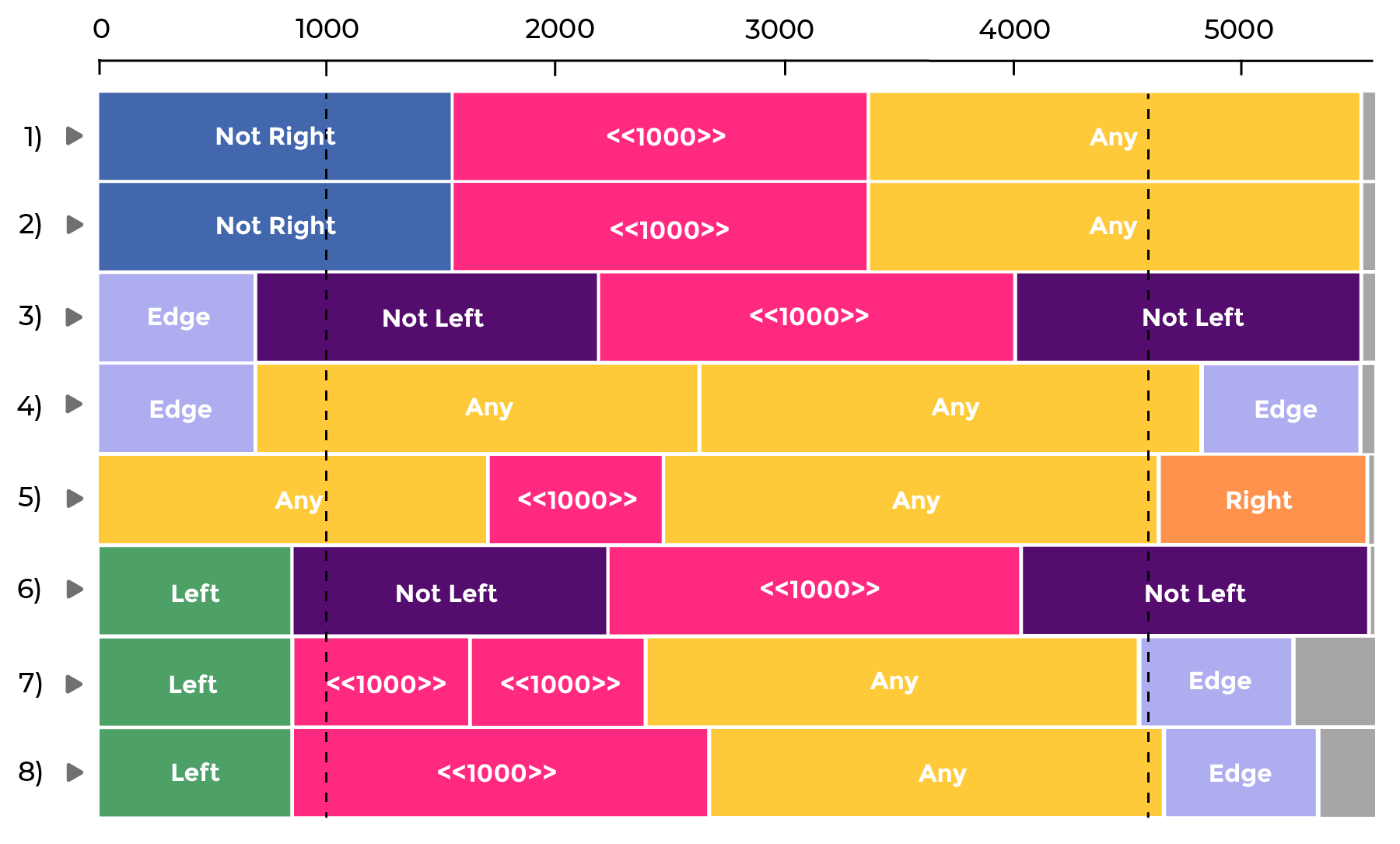

Our software can accurately predict outcomes and anticipate benefits from pattern reduction

Trim waste is reduced by patented algorithms

Reduced trim waste from primary slitting with patented algorithms designed to resolve the most complex of problems

Meet customers orders using any mixture of finished and semi-finished products

Accurately predict outcomes and anticipate benefits from pattern reduction

Our software can accurately predict outcomes and anticipate benefits from pattern reduction