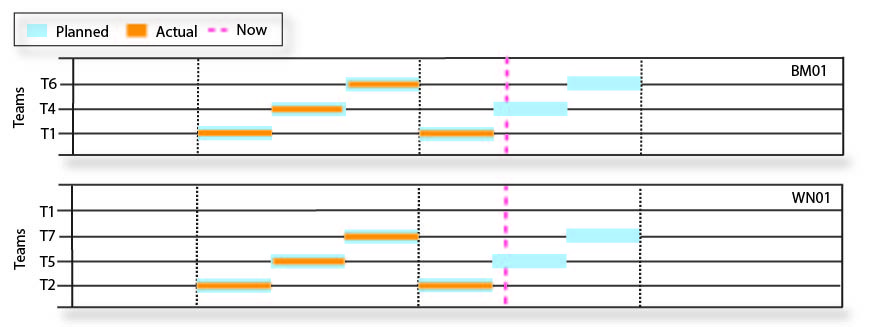

Tailored solution that evolves to meet for your business challenges

Experience the power of an industry-specific MES that deeply understands your business and evolves over time to meet the challenges of tomorrow

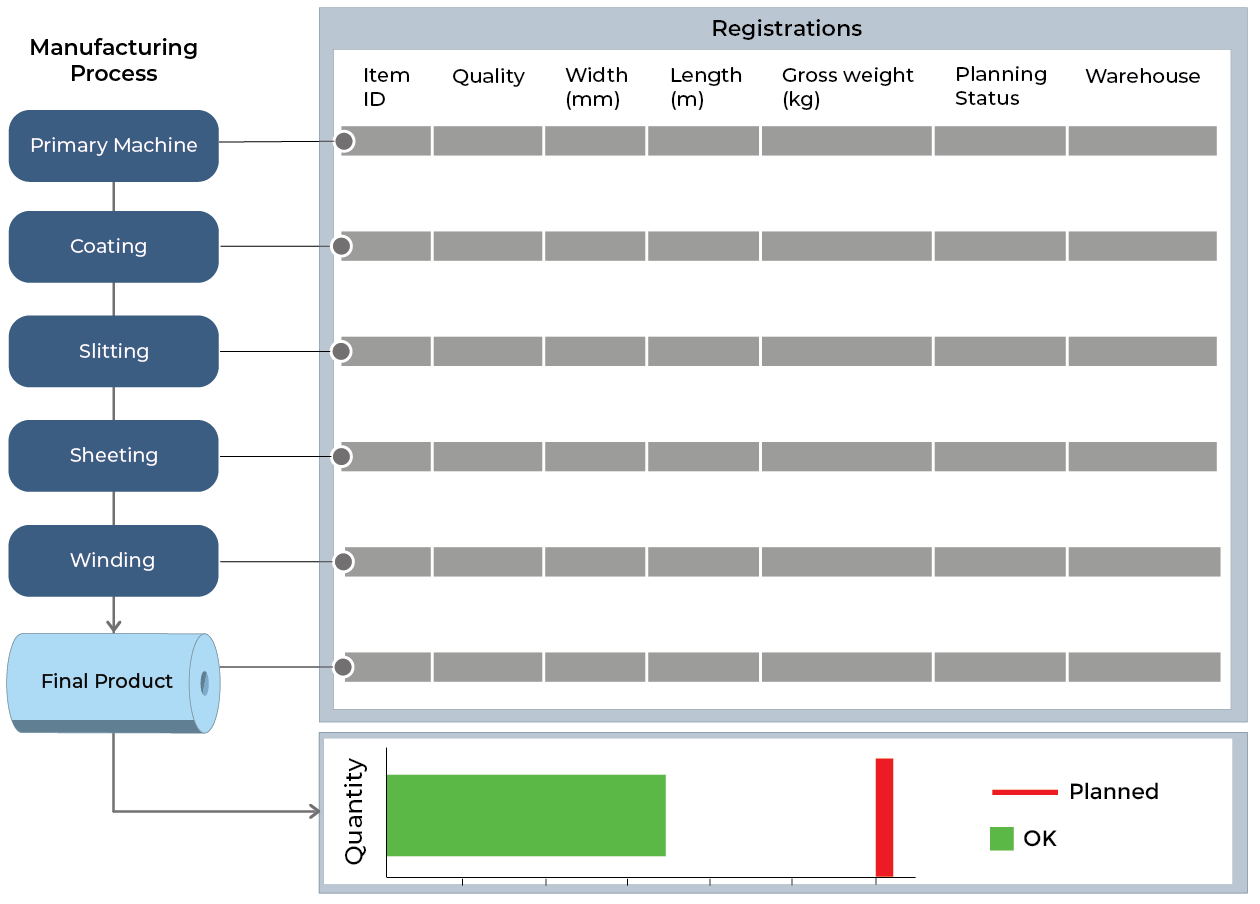

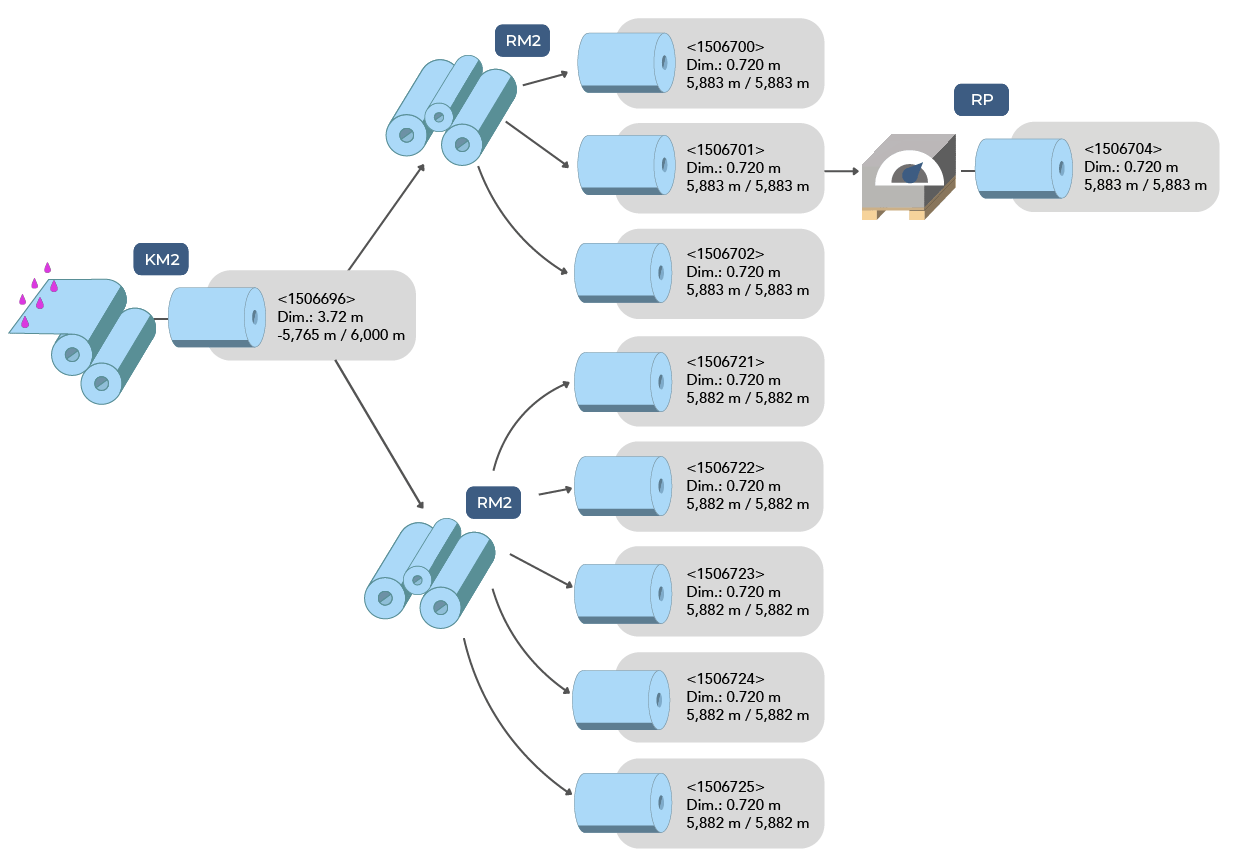

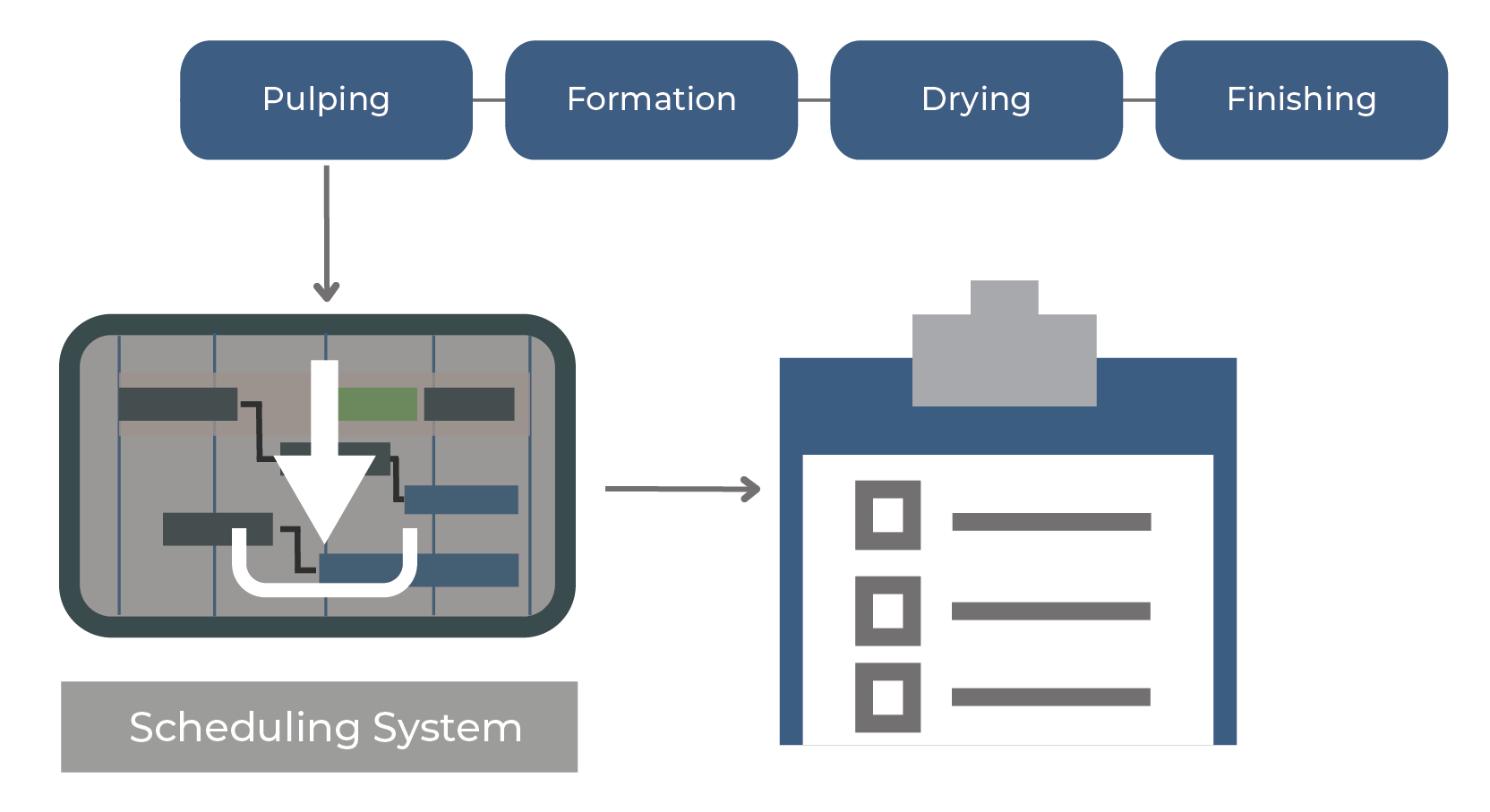

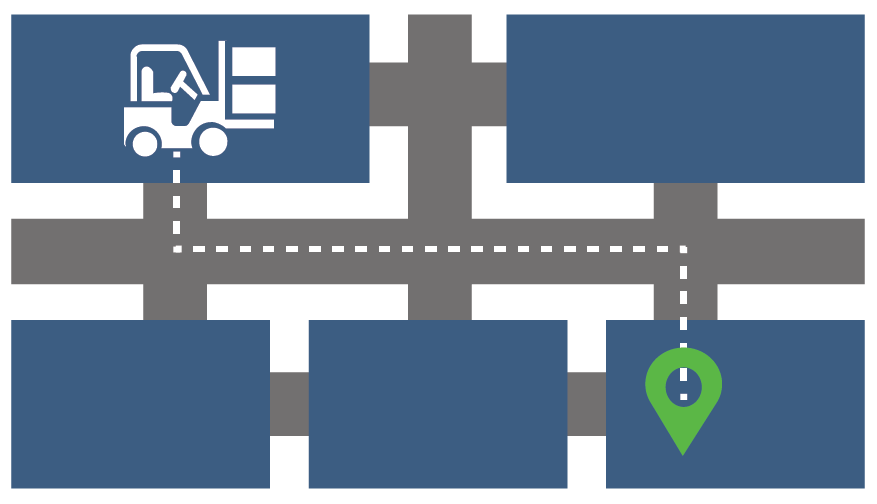

Seamless genealogy and traceability implementation

Overcome challenges effortlessly with our solutions, ensuring seamless genealogy and traceability in your operations

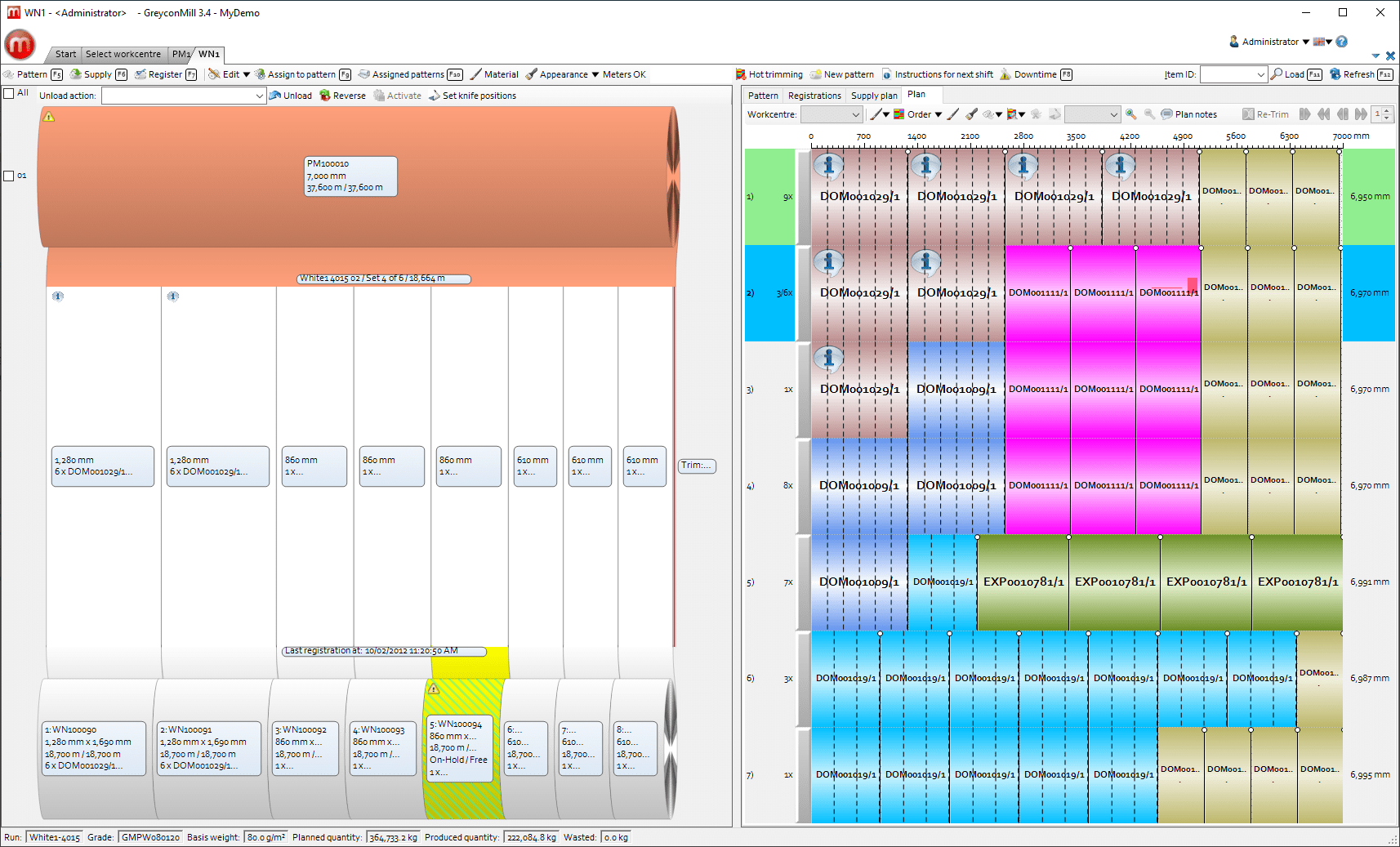

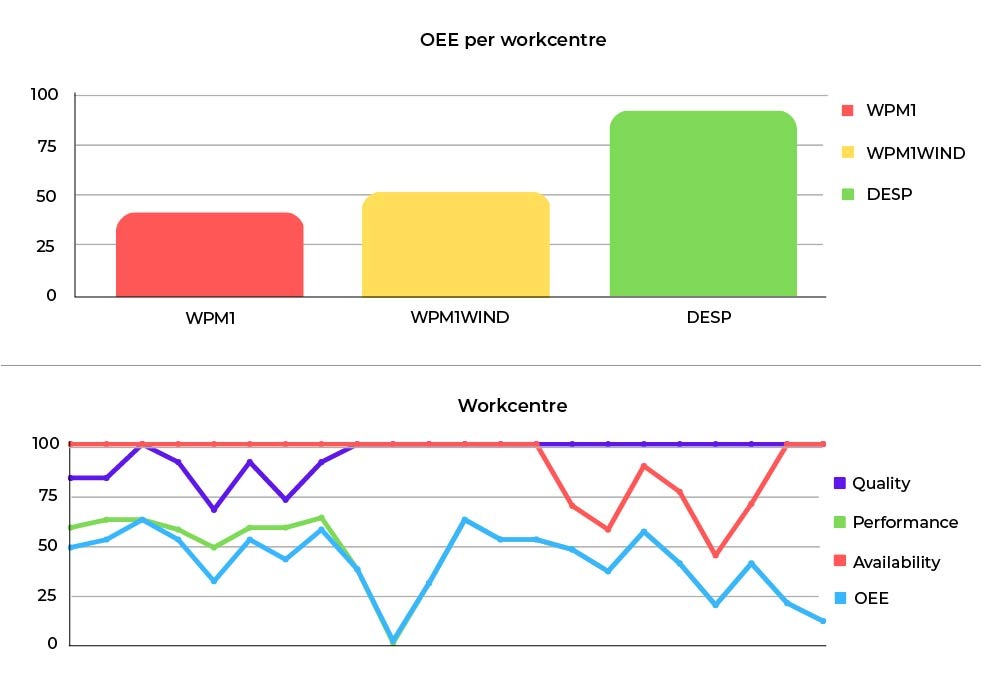

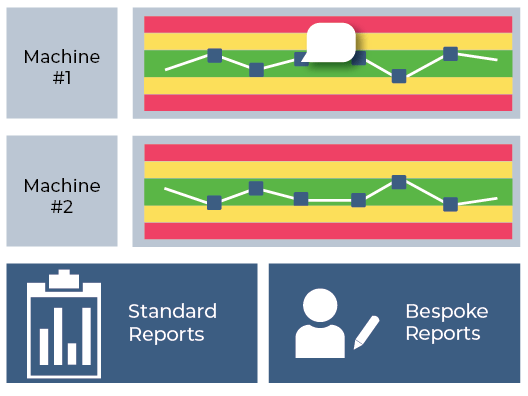

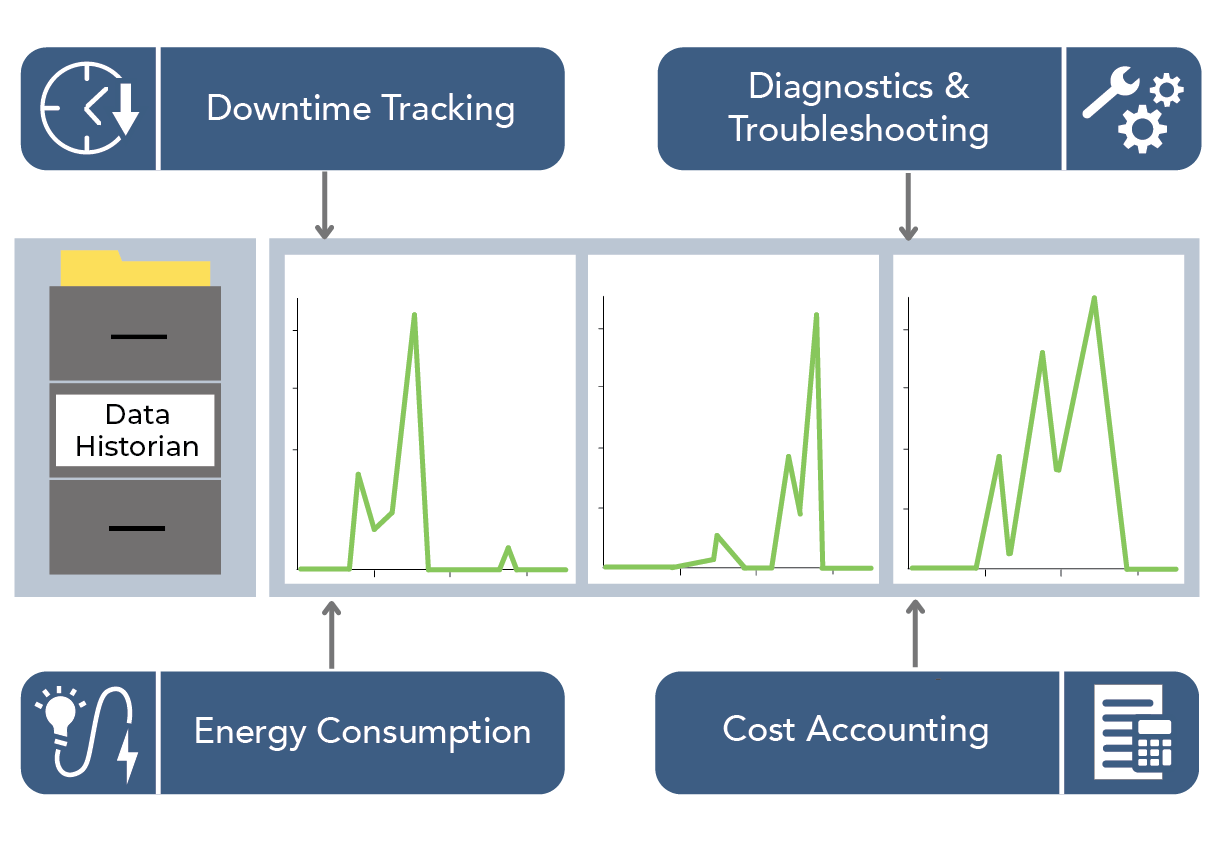

24/7 Optimisation-Based Support

Empower your operators with optimisation-based assistance, available round the clock, ensuring peak performance even in the middle of the night

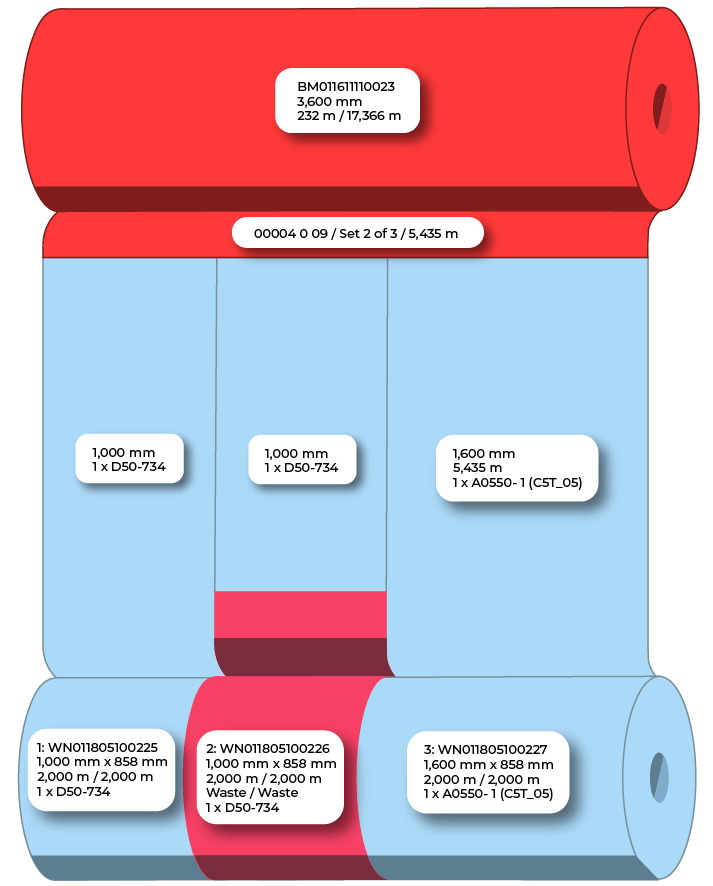

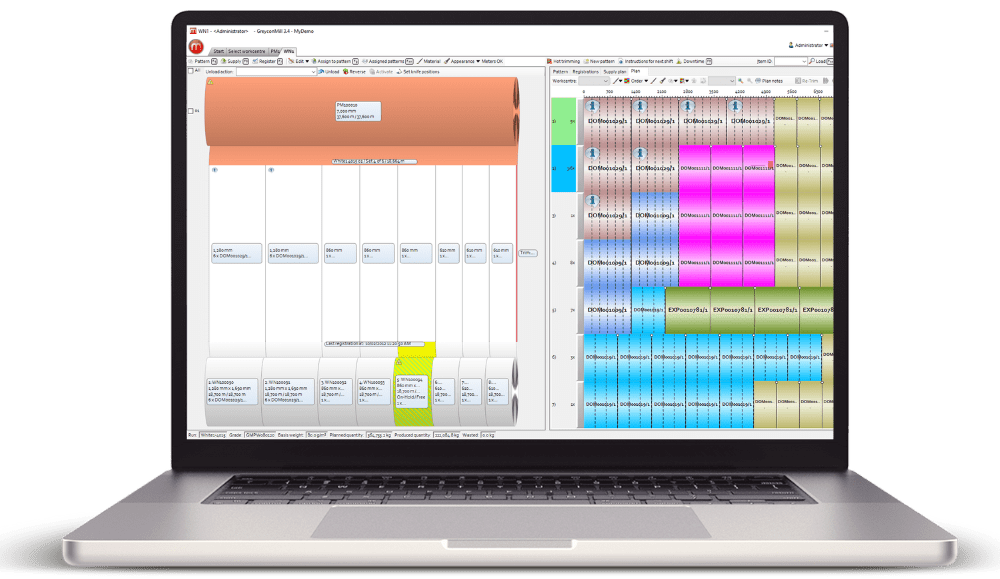

Trim waste is reduced by patented algorithms

Experience the power of an industry-specific MES that deeply understands your business and evolves over time to meet the challenges of tomorrow

Overcome challenges effortlessly with our solutions, ensuring seamless genealogy and traceability in your operations

24/7 Optimisation-Based Support

Empower your operators with optimisation-based assistance, available round the clock, ensuring peak performance even in the middle of the night