London, UK – August 18th 2016 – Greycon first implemented its advanced scheduling tool (S- Plan) at Fedrigoni’s Salto (Brazil) site in 2010. At the time the site was owned by ArjoWiggins, a world leading manufacturer of creative & technical papers with headquarters in France. The Brazilian subsidiary of ArjoWiggins was acquired by the Italian group Fedrigoni in 2015.

The Fedrigoni group is a leading international player in the production of graphic papers, security papers and self-adhesive products with a history of more than 125 years. Fedrigoni owns 13 factories worldwide, producing more than 470,000 tonnes per year of paper and films, and 705 million m2 per year of self-adhesive products.

Greycon’s S-Plan solution has successfully worked at the Salto site since 2010, with both ArjoWiggins and the current owners Fedrigoni. S-Plan was developed in 1988 as one of Greycon’s premier advanced scheduling solutions and interestingly one of the first customers then was Stoneywood mill in Scotland which belongs to ArjoWiggins group. With the release of the Greycon suite v7.6 in November 2012,

S-Plan was replaced by opt-Studio®.

The implementation of S-Plan at Salto mill in 2010 was so successful, both in terms of reducing production costs and yielding excellent results year on year that Fedrigoni decided to extend the Greycon scope to their Jundiaí site as well.

The implementation at the Jundiaí site is due to be completed by the end of November 2016. It will include Greycon’s world class trim optimisation system, X-Trim®, as well as the advanced planning & scheduling system, opt-Studio®, integrating with the plant ERP system (Protheus). Greycon solution will provide optimised trim solutions for the converting operations of Jundiaí site as well as improved visibility and efficiency gains with the integrated planning & scheduling process.

Greycon will also be upgrading the current S-Plan system at Fedrigoni’s Salto site to the latest GreyconSuite GR8.8 by the end of August 2016. Testing has already been carried out at the site, on which Greycon received very positive feedback regarding the new ‘tool’ opt-Studio®.

Abder Guezour, Global Business Development Director at Greycon states; “We are very pleased with the excellent results our solutions have produced and the long-standing partnership with the ArjoWiggins Group since the origins of Greycon, continued with Salto and now carried forward with Fedrigoni group. The regular release of new versions, the upgrade at Fedrigoni’s Salto site and the extension of the system to Jundiaí site is a testament to our continued efforts developing and improving our products to get the best results for our clients and to provide business continuity.”

About Greycon:

Greycon is the world’s leading provider of production planning, scheduling and manufacturing execution systems that have been designed specifically for roll-based & flat sheet industries. Greycon operate throughout the world. Greycon’s strength is the extensive range of specialist software solutions for Paper & Board, Plastic Films & Flexible Packaging, Nonwovens, Metals and Converting industries supported by powerful optimisation algorithms and a highly experienced team of consultants.

About Fedrigoni:

Since its foundation in 1888, Fedrigoni has specialised in fine paper for printing, editing, labels, bookbinding, packaging and paper products.

While this remains very much at the heart of the business, the company continually creates new paper processes and technologies that satisfy the ever-changing aesthetic and technical demands of the market.

Thanks to an advanced logistics system benefiting from 11 warehouse branches in Italy and seven abroad, Fedrigoni builds strong relationships with customers and provides them with highly tailored services, with very fast turnaround times.

www.fedrigoni.com

Press Contact: Mari Nisbet, mnb@greycon.com, +44 207 978 0700

London, England. – August 8th 2016 — In January 2016 Greycon implemented their world renowned system at Mel Paper, one of the largest manufacturers of recycled board in the food and general packaging industry.

Mel Paper is located near Thessaloniki and is the only manufacturer of recycled carton board in Greece. Mel Paper produces more than 100,000 tons of coated printing carton every year. These products are distributed to demanding markets across Western Europe, Africa and Asia.

“The implementation was carried out to the highest standard, it was completed on time and the communication throughout the process was flawless. Greycon has changed the way we work, we have never been more efficient!” commented Eleni Parisi, Project Manager at MEL Paper.

Mel Paper is an environmentally conscientious company and one of the key aspects of the implementation was to reduce the amount of waste produced. Mel Paper required a comprehensive solution that eliminates time consuming manual data entry and can increase the production output.

The Greycon system plans, schedules, trims and executes the production. Working seamlessly with SAPtm R3 it effortlessly transitions between the different modules. Since implementation the Greycon system has created significant cost savings for the company and optimised productivity.

Constantine Goulimis, CEO at Greycon says; “We created this system for companies just like Mel Paper who are looking for a more efficient production process. Through modern optimisation and powerful scheduling algorithms, the Greycon system efficiently records, tracks production and significantly reduces waste.”

About Greycon

Greycon is the world’s leading provider of production planning, scheduling and manufacturing execution systems, that have been designed specifically for coil-based & flat sheet industries. Greycon operate throughout the world. Our strength is the extensive range of specialist software solutions for Paper & Board, Plastic Films & Flexible Packaging, Nonwovens, metals and Converting industries supported by powerful optimisation algorithms and a highly experienced team of consultants.

www.greycon.com

About MEL Paper

MEL Paper is one of the largest manufacturers of carton board in Europe and the only company based in Greece. It produces more than 100,000 tons of coated printing carton each year for the general and food packaging industry. MEL Paper is an environmentally conscientious company using mainly recycled board as the raw material in its processes.

www.melpaper.com

Press Contact: Mari Nisbet, mnb@greycon.com, + 44 (0)207 978 0700

Greycon is happy to announce a significant breakthrough in the transformation heuristics, used inside X-Trim to reduce pattern count without affecting waste.

As outlined in the paper that can be downloaded from here, on a testbed of 120 problems, the new heuristic, called KBP, reduced the total number of patterns by 4.2% using (only) 0.24 seconds processing time per instance. The number of reductions in X-Trim will be a bit higher than this, thanks to synergistic effects with other heuristics. The savings are more noticeable on the larger problems, on the smaller ones the impact is not so big.

We had a small puzzle constructed to illustrate the new algorithm:

The question is how to re-arrange the tiles (reels) so that two of the rows are identical, i.e. only use 5 patterns. The solution can be found on page 6 of the attached paper.

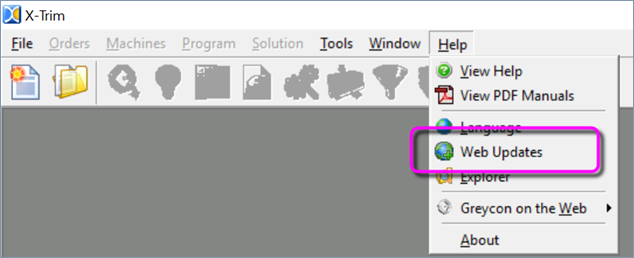

Greycon is applying for a US patent for this new algorithm, so, on legal advice, we could not make this algorithm available prior to filing. The application has now been filed and the new algorithm is available automatically via the Web Update function in version 8.6:

No settings need to change in X-Trim in order to take advantage of this new algorithm.

As the corresponding paper demonstrates, the idea behind KBP started as something that was relevant to only a small set of problems, but gradually, over the last 8 months, we have been able to generalise it. It is no panacea (there remains room for further improvement), but clearly is an important step in the path to fewer patterns.

Greycon is happy to announce the 8.5 release of its suite, which is notable for a significant reduction to the number of cutting patterns in our trim optimisation algorithms. The improvements have been benchmarked in a test suite of hard problems to be 9% lower than the previous version (8.4) and 18% lower against all previous versions. The reductions have key practical benefits for most of Greycon’s customers, as the number of cutting patterns is positively correlated to the workload of the slitter / winder crew. The savings have been achieved without any deterioration in waste performance. The trim optimisation algorithm is shared across all Greycon products (X-Trim, opt-Studio and GreyconMill), so the benefits are available to all customers.

In parallel, Greycon’s products have been adopted by numerous new customers in 2015, including AJ Oster (USA), Caprihans (India), Copamex (Mexico), Khanna Paper (India), SKC (USA), Taghleef (Spain) and Trident Paper (India). Existing customers have also extended their implementation to additional plants, including Arjo Wiggins (UK), GGB (China), Koehler (Germany) and Prolamsa (US & Mexico).

Commenting on developments, Greycon’s CEO Constantine Goulimis says:

“In a business like ours, project flow is uneven and sometimes difficult to manage psychologically. Our mitigation strategy is to have very conservative finances; we are also buffered by long-term support contracts from our loyal customer base. Still, we got very excited at the beginning of the year at the prospect of a very big project, which unfortunately did not materialise. Although Q1 was almost devoid of new projects, Q2 has been just the opposite. Both our global footprint and continued investment resulting in functional superiority factor into this.

Testament to our expertise and leaving no doubt that our solutions can lead to material benefits, one of our customers recently shared a year-long analysis of results; by their measurements, overall machine utilisation increased from 97.4% to 97.6% – this small difference translates to 3,000 tonnes of less waste. Our work of course never ceases: since the 8.5 release in May 2015 we are releasing today (26th June 2015) the 8.5 P01 version; this contains an additional 1% reduction in the number of cutting patterns.”

Supported customers can obtain the latest version automatically through the web update process.